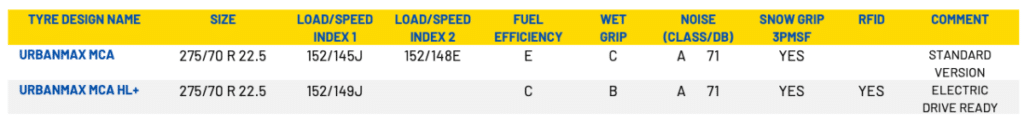

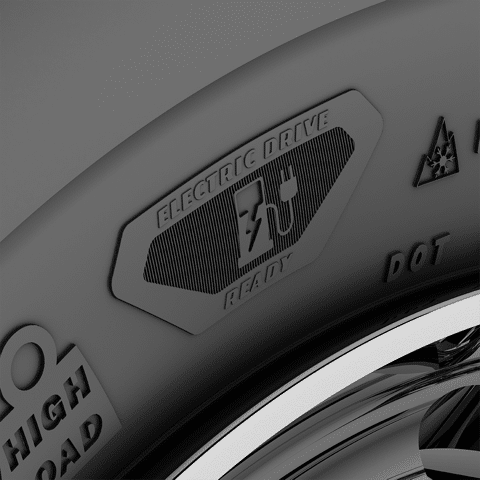

| *Designed to support lower energy consumption and electric drive ready The city bus market is in an unprecedented period of transformation. Electrification, autonomy and accessibility, including on-demand services, are revolutionising urban mobility. Goodyear has launched the URBANMAX MCA HL+ tyre to provide a solution for operators seeking to maximise the efficiency of their current fleet and prepare for the future.Maciej Szymanski, Marketing Director Commercial Europe for Goodyear: “Bus operators are under increasing pressure to meet environmental targets whilst adapting to changing trends in urban mobility. Goodyear’s focus is to simplify the move towards a climate-neutral future by providing the technologies to win in a fast-changing environment for personal mobility. Our aim is to support bus fleet managers in lowering the carbon footprint by driving energy efficiency with low-emission tyres as well as smart tyre monitoring systems.” Electric drive readyBased on the proven URBANMAX MCA design, the new MCA HL+ is adapted to support additional battery loads while enhancing lower energy consumption. The technology in the tyre, which includes a new tread compound, design and construction, supports the need for operators to reduce CO2 and noise emissions, particularly in densely populated areas.The URBANMAX MCA HL+ is an all-position tyre with high-load structure enabling an 8-tonne axle load capacity required by modern electric or hybrid buses.“The URBANMAX MCA is known for its high mileage potential, traction and all-weather grip performance required in demanding urban environments. Since many years, this product line is a trusted choice of leading transportation companies across Europe as it is catering to the needs of both combustion and alternative drive trains. The new URBANMAX MCA HL+ size offers lower rolling resistance to further enhance energy and fuel efficiency as well as an increased load capacity supporting range extension for electric buses.” says Szymanski. Fit for demanding city application and all-weather conditionsWhilst energy efficiency is at the forefront fleet managers’ minds, durability remains a key factor in running bus operations. Buses have to tackle a wide range of demanding road conditions including kerb impacts, potholes, speed humps, urban areas with tight turning circles and regular stop-start driving.As public transportation keeps cities moving, service needs to run whatever the weather, therefore the URBANMAX MCA range is fit for all-season operation and has a 3PMSF sidewall marking related to its responsiveness on snowy and icy surfaces.Any downtime can heavily disrupt passenger schedules, so Goodyear has focused on a range of technologies that combine robustness with energy efficiency. The company also integrated RFID tags to allows simple identification and connectivity to tyre management and tracking systems, further streamlining tyre management.Supporting green goals of transportation companies, the full range is also compatible with the Goodyear Retreading program. Technology features incorporated in the URBANMAX MCA HL+The innovative tread design has an optimized rib layout to ensure even contact pressure distribution, shoulder robustness and stress reduction.A low hysteresis tread ensures cool running capabilities reducing heat build-up or energy loss and offering excellent wet grip for high traction at poor weather conditions.‘Flexomatic’ sipes in the centre ribs, supported by block edge siping improve the braking performance. The Flexomatic sipes close when rolling through the footprint so that the tread blocks interlock. This makes the tread stiffer and more robust whilst still maintaining high traction in more challenging weather conditions.Incorporated Interlaced Strip Technology assures less deformation in the carcass and creates a uniform pressure distribution across the footprint.URBANMAX MCA HL+ has a reinforced sidewall and will protect the tyre to the higher impact risk within the urban environment.Wear indicators indicate the remaining thickness of the protective layer and when the tyre should be reversed, effectively giving it a second life. |